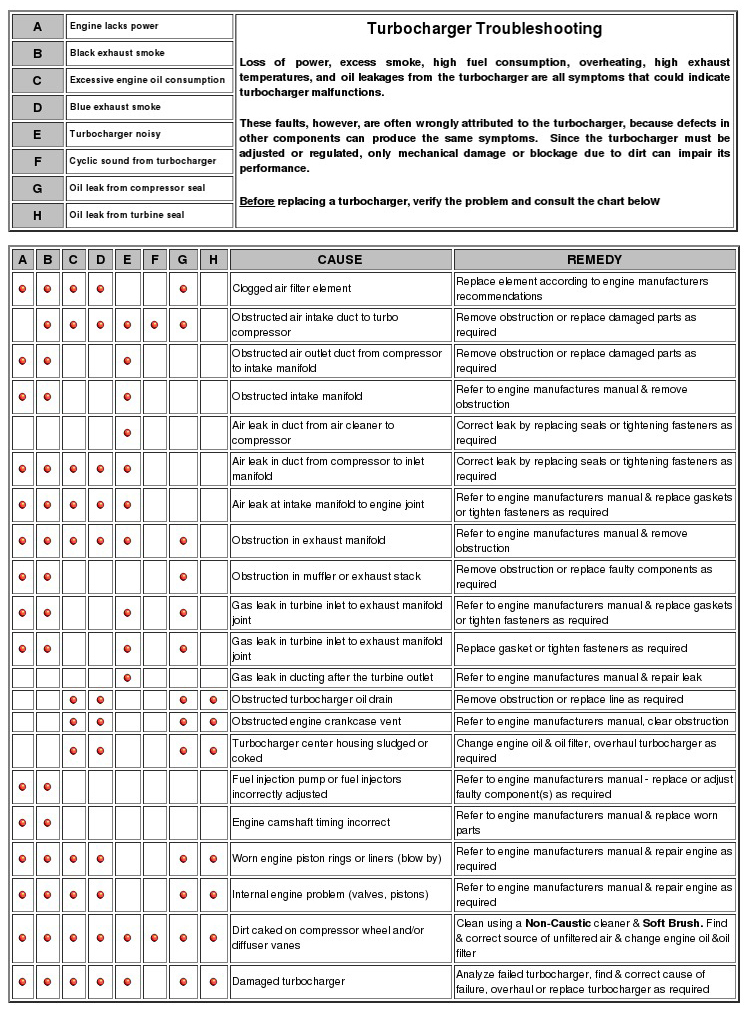

Use the Troubleshooting Chart below to help diagnose the problems you

may be having with your Turbocharger!

COMMON CAUSE OF TURBO FAILURE

- Hot shut down. That is, turning engine off prematurely without allowing sufficient time for turbo to cool.

- Infrequent oil, Oil filter, and Air filter changes.

- Foreign matter and / or obstructions in turbocharger air or oil system.

- Improper engine maintenance. Operating engine when out of tune or in need of adjustment or maintenance.

- Related engine part or engine failure. For example, a cracked head, broken or worn piston rings, blown head gasket, clogged radiator, and impact damage due to accident.

TURBO INSTALLATION GUIDE

- Check the operation of engine to ensure it meets manufacturer’s specifications.

- Replace oil supply line in all gasoline applications.

- Do not use a thread sealer (silicone) on any oil line.

- Check oil drain for restrictions effecting flow such as kinked or deteriorated rubber sections and sharp bends.

- Check for contamination and obstructions such as kinked, worn, and plugged oil lines and oil passages. If applicable, check inter or after cooler for the same. Remove and thoroughly clean intercooler.

- Replace air filter element. Check for flow restrictions in both intake, and exhaust, including catalytic converter.

- Inspect for and remove all foreign objects from the intake air tract, and secure all hoses.

- Replace oil and oil filter. replace any crankcase breather elements.

- Verify that the actuator “c” clip is secure.

- Verify oil drain direction is vertical.

- Verify tightness of all clamps and bolts, secure lock tabs if applicable.

- After installation, ensure to remove all tools from engine compartment.

- Before starting engine, disable either fuel or ignition system to allow engine to be cranked without starting. Engine must be cranked until normal oil pressure is achieved. Once oil pressure is achieved, then you may start engine. Repeat after all oil changes.

Function of a Turbocharger

Power output is determined by the amount of fuel that can be burned in a given time. For proper combustion, the fuel needs an adequate supply of air. To increase power more air is required.

Power output is determined by the amount of fuel that can be burned in a given time. For proper combustion, the fuel needs an adequate supply of air. To increase power more air is required.Since the volume of the engine cylinders is fixed, the air supply can only be increased by using some form of compressor. The turbocharger increases the air supply by means of a compressor driven by the waste exhaust gases.

Since the exhaust gas energy is used to improve the overall efficiency of the engine, the fuel consumption is reduced resulting in LOWER operating expenses.

YOUR TURBOCHARGER'S WORST ENEMIES

CONTAMINATED LUBRICANT….

Bad lubricant will cause scored shaft journals and bearings, block oil holes and plug seals, resulting in heavy oil leakage.

FOREIGN OBJECT INGESTION….

Damages turbine and compressor wheel blades, causing wheel imbalance and rotational instability, with resulting damage to seal bores and bearings

ENGINE PIECES, SHOP TOWELS, SAND, DIRT OR METAL FILINGS….

These are all externally-introduced causes of turbocharger failure, and as such, can be lessened or eliminated through proper maintenance of engine air intake and oil filtering systems.

YOUR TURBOCHARGER'S BEST FRIEND!

CLEAN LUBRICANT….

Always be sure to keep your turbocharger well maintained with a good quality lubricant. It will prolong its life and enhance its performance.